What engineering factors must be implicitly evaluated in an oil well?

Greetings friends, supporters and members of the hive platform, especially those who contribute to the development and dissemination of STEM content.

In this opportunity I want to share with you a quite simple and friendly content related to the intrinsic aspects that brings the engineering involved behind an oil well, I know that by now many of you have read a lot of my content related to the oil industry, but I know that with the reading of this article you will be able to have a friendly reading, where you will find even a little history of the oil industry, and of course as usual the most important engineering aspects behind an oil well.

Before we go into any kind of detail involving the engineering behind an oil well, I think it is very pertinent that you get to conceptualize what an oil well is.

An oil well is nothing more than a hole that connects the surface to the subsoil, taking into consideration that the subsoil is where the rocks are that store not only oil, but can store oil and natural gas, even if the well is only oil, in the same way there is a certain amount of gas associated with oil fields.

The main objective of building an oil well is to serve as a means of transport to exploit this hydrocarbon that is in the subsoil from the bottom to the surface. In other circumstances the well can also be built to exploit dry gas deposits.

What historical aspects can be evaluated in the evolution of oil wells?

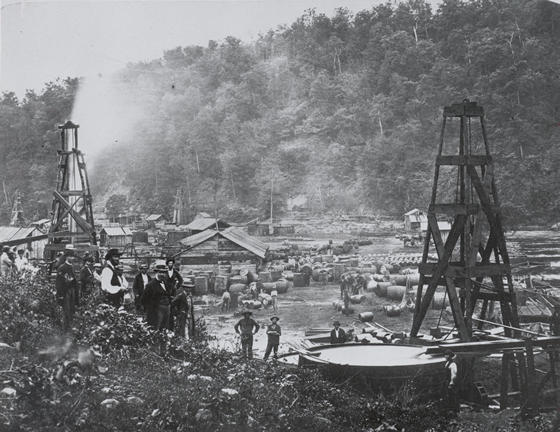

It is said for a reason that one of the first civilizations of great importance for humanity was the Chinese civilization, since it was in China the first country to build the first oil wells, it is worth noting that the depth of these first wells were not very deep compared to the depth of the wells being built today, For example the depth of the first oil wells drilled in China was approximately 240 meters or its equivalent of 790 feet, this first development in the drilling and construction of oil wells by China was by the middle of the year 347 after the birth of Jesus Christ.

Later developments in the drilling and construction of wells occurred in other parts of the world, especially when we talk about the incorporation of new technologies such as percussion drilling, all this happened in the Caucasus area of the country of Azerbaijan.

For the American continent, the drilling and construction of oil wells took place in North America, where the first commercial oil well was in Oil Springs in Ontario in 1858.

Among the new technologies that were gradually replaced highlights the percussion drilling to the rotary drilling, even first most of the wells that were drilled were vertically drilled wells, then evolved into another form of drilling in different directions using the technique of directional drilling.

All these advances to optimize the processes of construction and drilling of wells also made it possible to incorporate an academic, scientific and engineering form to study all the processes within the drilling of oil wells.

What engineering features are included in the life of an oil well?

The planning according to place to doubt is one of the aspects within the engineering that more are influential within the life of a petroleum well including its different areas, that is to say it is necessary to plan diverse programs from the processes of exploration to find the petroleum deposits that are candidates (prospective) to contain hydrocarbons happening through the perforation and construction of these wells until contemplating the operational activities in the production of petroleum and/or natural gas of these oil wells.

It is important to mention that in planning aspects there are several factors to consider before starting with the drilling and construction of an oil well, it is necessary the scientific and engineering support of professionals in the area of geology to identify the geological objective that makes viable the drilling and construction of the oil well, this objective includes a study about the characteristics of the reservoir where the oil and/or natural gas is located.

If the well to be drilled is intended to meet production objectives, the reservoir reached by drilling from the surface to reach very deep into the subsoil is to optimize hydrocarbon production and manage the reservoir's drainage capacity by drilling and constructing the well.

If, on the contrary, the drilling and construction of the well is planned with the intention of carrying out exploration and geological evaluation activities, it is because with the drilling of such exploratory well it is intended to be able to confirm the existence of a reservoir containing hydrocarbon storage whose characteristics are of a future production that can be attractively marketed.

Not only is it feasible to drill a well to meet net exploration or production objectives, there are also cases in which it is necessary to plan from the point of view of oil engineering the drilling and construction of wells that will make injection wells. Such injector wells will simply serve as a means of transport to inject fluids that will stimulate the producing reservoir to improve its porosity and permeability characteristics, so that the oil that has been left behind but due to low permeability and high viscosity is difficult to extract can be produced.

Once the trajectory that the well should take during its drilling and construction is determined, a series of lithological factors must be previously calculated, which are essential to design for example the drilling mud curve. Among these factors that must be previously calculated are:

The pore pressure: this pressure is the pressure with which fluids such as gas and oil are contained in the subsoil, it is very important to calculate the pore pressure because it is crucial to know the density with which it will be possible to make the design of the drilling fluid.

Fracture gradient: this fracture gradient is the pressure that can resist the lithological formation of the subsoil at different lengths, this pressure is also a determinant for the design of the density of the drilling fluid, since the drilling fluid must be dense enough to hold the formation fluids but should not generate a pressure that exceeds the fracture pressure.

In conclusion, for the drilling and construction of the well, everything related to the muds that may be presented by the subsoil geological conditions must be planned, as well as contemplating in the design everything related to the equipment with which the well is going to be drilled and constructed, from drill bits, drill pipe, casing, well cementing, drilling fluid, in short, in such planning a program of drilling and construction of a well must be elaborated that describes the procedures step by step for such construction of the oil well.

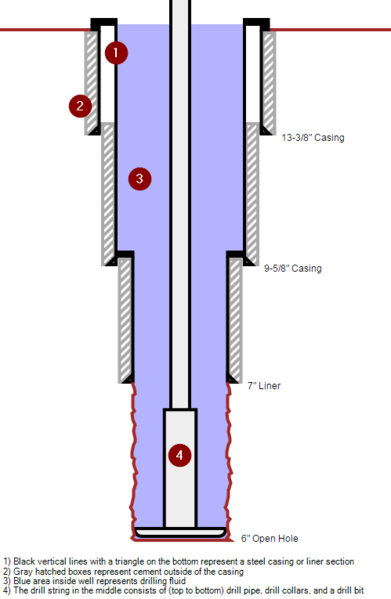

Logically the oil well has only been defined in the program, however it is necessary to reach the execution of the drilling of the well. From experience in the area of drilling I can tell you that a practical way to start drilling an oil well is to make a mechanical diagram of the well that includes the phases of the well in which the well will be built, and above all and most importantly to know how the distribution of the casing in the well will be.

In the image above we can see a mechanical diagram of the well, clearly you can see that not all phases are contemplated, only the distribution of the surface liners, intermediate and the 7-inch production liner.

Already after the guide that can mean the mechanical diagram from the engineering point of view, it only remains to prepare the drilling mud (drilling fluid) for each of the phases of the well, have all the equipment in place as drill pipe, drill string and tell to drill the well according to the drilling program.

What is the production stage of an oil well like?

The production stage is one of the most important stages of the oil well, since all the human effort together with the talent in the engineering design of such well is rewarded with the production of the well.

Once the well is completed, the drilling platform is removed from the well, leaving the well subject to production, for it commonly is left installed a set of valves called Christmas tree, so that the Christmas tree is installed is because the most probable thing is that the well I am producing by natural flow, next I present/display to them an image where it is appraised a well producing with an installed Christmas tree in the mouth of the well:

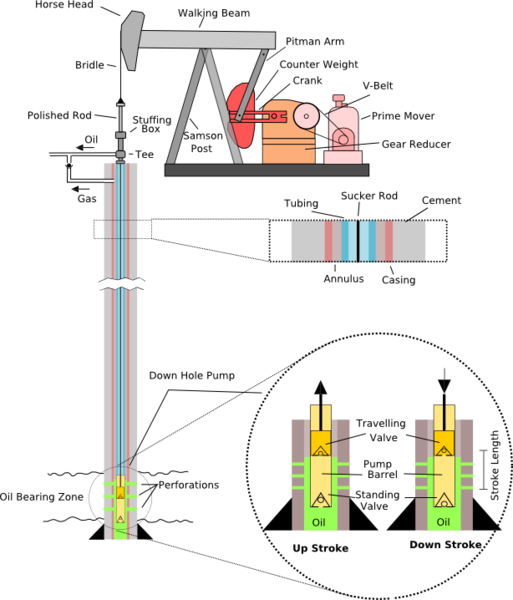

Not in all cases we will be able to see surface wells with this set of valves called Christmas tree, since the production of the wells and the way they will be produced will depend on the pressure (energy) that the reservoir has, so if the energy is not enough it is likely that a type of mechanical pumping will have to be installed which can be a rocker arm for example, it can also be a progressive cavity pumping, or an electro-submersible pumping and even an artificial lift by gas lift. Below I show a picture of a mechanical pumping type by means of a rocker arm:

Associated costs and impact on what it means to drill, build and produce an oil well

When a well is drilled there are costs associated with that drilling and construction activity, now these costs depend on the drilling rate, that is to say the daily rate that the platform consumes due to the costs not only of drilling but also of the maintenance of the engineers and some workers who may spend the night at the location.

If the drilling time of the well exceeds the estimated time according to the drilling program then you would be spending money that is above the budget according to the program, this in turn must be correctly justified, that is to say, the reason for those unproductive times that made the drilling costs rise must be well explained through some reports.

There are other economically evaluable scenarios, and it is when the costs of maintaining the production of a well exceed the income from the production of that well, for example when oil prices fall, or even when the taxes for the extraction of the hydrocarbon are very high, may be the ideal conditions to abandon the well for only that period of time, until at least the price of oil can rise again.

Well friends, I hope this summary of the engineering and economic aspects that have been addressed in this post can be useful for many curious and apprentice oil engineers and the oil industry in general, says goodbye to you and until a next delivery your friend @carlos84.

Note. The following image was used for the cover image: West Texas Pumpjack

Recommended References

https://twitter.com/CARLOSJB84/status/1320917894839095301

#posh:

https://twitter.com/CARLOSJB84/status/1320917894839095301?s=20