Electro-Hydraulic Basics: Automating Multiple Cylinder

1. Introduction

We already talked about controlling multiple cylinder in the previous blog. Today, we elevate the discussion by creating a circuit that automate a process involving multiple cylinder. Similar to the blogs in this series, we define the process and interpret the process to establish the correct circuit to simulate. The process is described as

A box in a vertical stack is to be stamped with a sticker. A cylinder A pushed the boxes out from the stack and Cylinder B stamps the sticker to the box. Cylinder A retracts at after the box is already stamp with a sticker. The process is continuous once activated by pressing a button and can be deactivated by pressing a stop button. To confirm the cylinder position at any given time, a pair of limit switch is placed in each cylinder.

We can obtain the sequence A+, B+, A-, B- to be achieved continuously by two hydraulic cylinder. Also, we need four sensors to detect the position of the cylinder at any given time. In the next section, the circuit is shown and discussed in details.

2. Circuit and Simulations

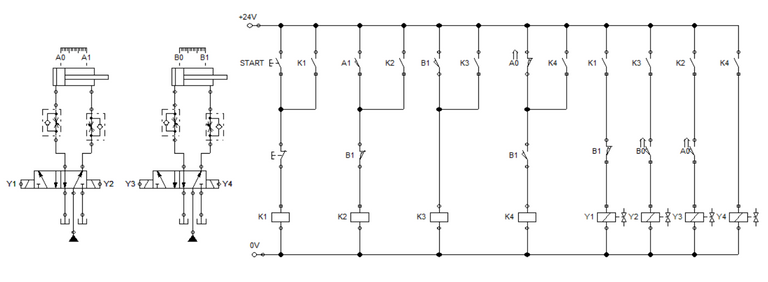

Figure 1: Electro-Hydraulic

The hydraulic actuation circuit in this blog is configured in the same way as to the previous blog. The cylinders are driven by double solenoid 5/2 way directional control valve. As discussed in the previous blog, the solenoid actuated valve allows us to freely extend and retract the cylinder. For the electrical controller, we used four relays and solenoid to achieve the described process. The relay K1 is driven by the start, stop and contact K1. The configuration shown in Figure 1 enables relay K1 to activate when start button is pressed. Contact K1 in series with sensor B1 is connected to solenoid Y1, which enables solenoid Y1 to energized at K1 activation. Solenoid Y1 opens port B of the 5/2 way directional control valve to extend cylinder A. This is shown in Figure 2.

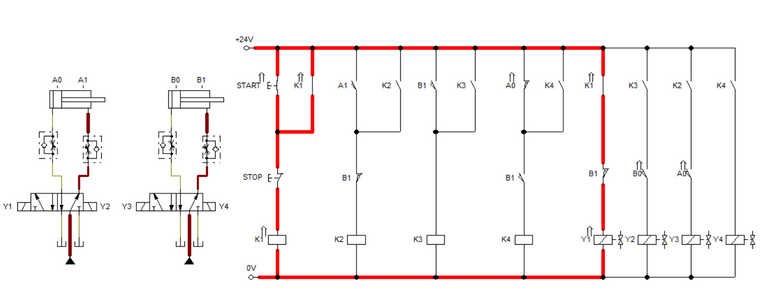

Figure 2: Start button is pressed.

Relay K2 is activated when cylinder A is fully extended. We connect sensor A1 and contact K2 in parallel to activate and sustain relay K2 respectively. Contact K2 drives solenoid Y3. Closing K2 results to activation of solenoid Y3. Solenoid Y3 actuates cylinder B to extend fully.

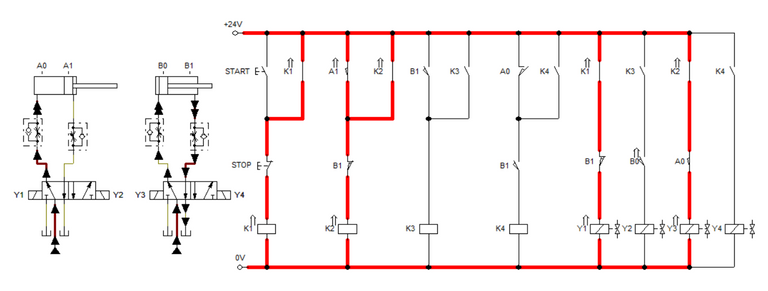

Figure 3: Relay K2 is activated.

When cylinder B reaches the full extended length, sensor B1 detects it and activate relay K3. To sustain activation, we connect a latching contact K3 across sensor B1. Solenoid Y2 is directly connected to contact K3 so that when cylinder B reaches full extended length, cylinder retracts by actuating solenoid Y2. The configuration is sown in Figure 3.

Figure 3: Relay K3 is activated.

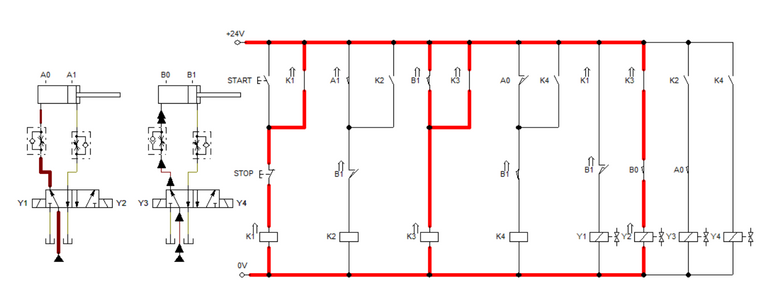

When K3 is activated, solenoid Y2 retracts cylinder A to initial position. Relay K4 is activated by sensing the position of cylinder A at full retraction. Sensor A0 sends a signal to activate relay K4. Relay K4 drives the contact in series with solenoid Y4. It result to opening port C at 5/2 way DCV at cylinder B. Cylinder B retracts. To repeat and automate the process, we put latching contact at start button and strategically placed the sensors all through out the circuit. The placement of the sensor in the controller allow us to achieve the correct sequence and automate it. The simulation is shown in Figure 4.

Figure 4: Simulation

3. Conclusion

In this blog, we create a electro-hydraulic circuit that automates a basic sequencing action of two cylinders (actuators). we discussed on how we strategically placed sensors and relay to achieved the A+, B+, A-, and B- sequence and repeat the process. We highlighted the role of correctly placing and linking the sensors to achieved the task at hand. Similar to the previous blog, we need to fully grasp the sequence of action needed in the process before we can appropriately place the sensors.

4. References

[1] Hydraulic Basic Level. online access

[2] Hydraulic Advance Level. online access

[3] Electro-Hydraulic Basic Level. online access

[4] Electro-Hydraulic Advance Level. online access

(Note: All images and diagram in the text are drawn by the author (@juecoree) except those with separate citation.)

If your are interested in pneumatic and hydraulic series, you can read:

Pneumatic and Electro-pneumatic

1. Pneumatic Basics: Direct Control

2. Pneumatic Basics: Indirect Control

3. Pneumatic Basics: AND and OR Logic

4. Pneumatic Basics: Memory Circuit and Speed Control

5. Pneumatic Basics: Dependent control

6. Pneumatic Basics: Multiple Actuators

7. Electro-pneumatic Basic: AND and OR Logic

8. Electro-pneumatic Basics: Interlocking, Latching and XOR logic

9. Electro-pneumatic Basics: Distribution of Workpiece

10. Electro-pneumatic Basic: Ejecting a workpiece

11. Electro-pneumatic Basics: Basic Automation

12. Electro-pneumatic Basics: Automation with Counter

12. Electro-pneumatic Basics: Automating with Timer

13. Electro-pneumatic Basics: Cementing Press (Time Dependent Control)

14. Electro-pneumatic Basics: Embossing Device

15. Electro-pneumatic Basics: Bending Device

16. Electro-pneumatic Basics: Introduction to Logic Module

17. Electro-pneumatic Basics: Automating with Logic Controller

18. Electro-pneumatic Basics: Logic Controller for Multiple Actuators

19.Electro-pneumatic Basics: Time-dependent control with Logic Controller.

Hydraulics and Electro-Hydraulic

20. Hydraulic Basics: Direct Control

21. Hydraulic Basics: Indirect Control

22. Hydraulic Basics: Dual Pressure Value and the AND Logic

23. Hydraulic Basics: Shuttle Valve and the OR Logic

24. Hydraulic Basics: Sequencing Multiple Cylinders (Actuators)

25. Hydraulic Basics: Automating Multiple Cylinders (Actuators)

26. Electro-Hydraulic Basics: Direct and Indirect Control (Part 1 of 2)

27. Electro-Hydraulic Basics: Direct and Indirect Control (Part 2 of 2)

28. Electro-Hydraulic Basics: Two ways in Implementing AND logic

29. Electro-Hydraulic Basics: Two ways in Implementing OR logic

30. Electro-Hydraulic Basics: Circuit with ON and OFF-delay Timer

31. Electro-Hydraulic Basics: Automating Processes (1 of 3)

32. Electro-Hydraulic Basics: Automating Processes using Timer (2 of 3)

33. Electro-Hydraulic Basics: Automating Processes with Counter (3 of 3)

34. Electro-Hydraulic Basics: Controlling Multiple Cylinder

Posted with STEMGeeks