Well We Found The Problem, Naturally This Is Our Game

Well Hello There Hivers And Technicians

It's been a while eh Ladies and Gents.

Laughs who am I kidding it's barely been a week since my last post in the #Hivemotors community, however it feels like it has been ages! I use to write frequently in this community, the thing is I just found some other cool stuff to share in other community's.

It's not that I don't have anything to share for this community! Believe me I have a lot to share, more than I have for any other community! But if I have to be honest since it's my job it does get somewhat tiring to come home and do some more typing around topics that involves mechanics.

But I went through my possible posting contents and I found one that I would like to share now! Lets get to it!

Oh by the way I hope every one is still doing great!!

Feel free to comment below if there is anything in particular that you might want me to do a run through on. When I get a similar job I will without a doubt give you a tagging in the post!

A while back I wrote a post about a Isuzu that was repaired at the dealers and how they just couldn't find exactly pin point the actual problem. Check that post out here.

Sheeessh I cant believe that was almost a month ago! Time flies as we draw closer to December and the holiday seasons!

What We Actually Repaired

Well a week or so ago I fitted the gearbox after we did the necessary repairs that was needed. Along with that we fitted a new clutch.

The only repairs we did inside the gearbox was replacing the input shaft which contains the fourth gear. But the fourth gear is actually the power input to the gearbox so it messed with all of the gears.

The clutch it had in the vehicle was a new clutch that was recently fitted, however because of the gearbox problems the vehicle didn't drive as intended and there fore you had to sort of play on the clutch to actually get the vehicle moving and this caused the clutch to burn over time.

I am glad that they authorized us to actually do the clutch, usually they ask us why do we want to do more than intended.

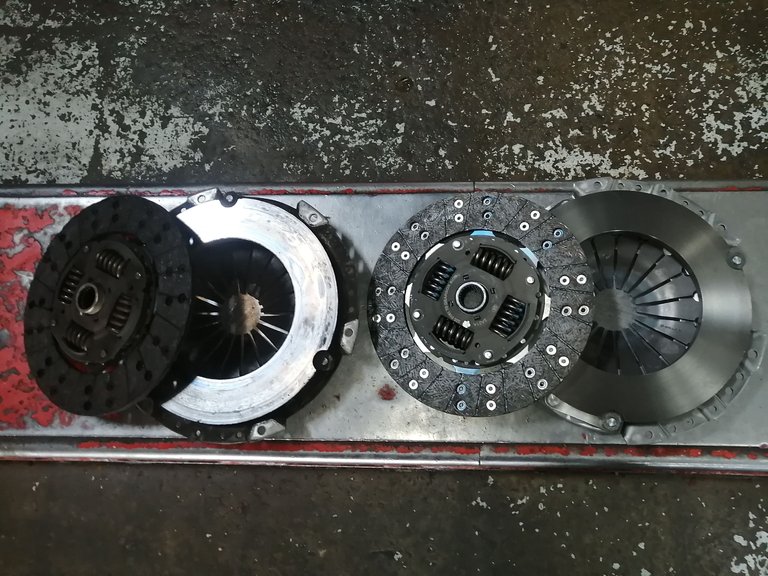

In the image below you can see the old clutch on the left and the brand new one on the right. Needless to say I'm sure everyone can see the big difference between them.

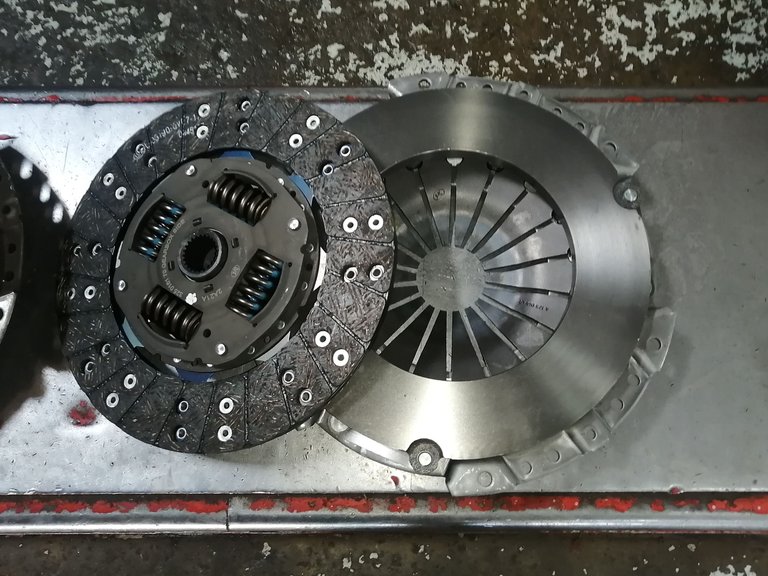

A closer up view of the new clutch. I always say this, I know I might be a little repetitive at times but sheesh a new clutch people. I find it very very attractive.

The old and burnt clutch, so without a doubt you can't make this work there is just no way possible. Perhaps if the pressure plate was still in a good condition one might only need to replace the clutch disk itself, but as you can see that the pressure plate is full of those black spots. (Pressure plate on the right, clutch disk to the left.) However this is a total trash and needs to be thrown away.

Fitting The Flywheel And Clutch

As usual when doing a clutch overall we tend to skim the flywheel as well. Otherwise it might lead to premature failure of the clutch. A lot of folks out there only sands it down with sanding paper. 😅😂 And let me tell you that is not the way to go. Do the effort and send it to the folks who have the right equipment as well as the right knowledge.

In doing so you might just save yourself some time and effort, perhaps a buck in the future!

Nice and clean skimmed flywheel. We always make sure that the flywheel is skimmed according to specs even if we took it to professionals to do. We have a book with all of the specs, be damned if I knew where we got it. Notice the 18mm written in green on the flywheel I know it's barely visible. That means that the recess of the inside should drop down 18mm from the side which is higher than the platform.

Usually when you buy a new clutch you would get a clutch alignment tool with, that it the black and yellow object stuck in the middle of it. In my opinion we've gotten one at least 60% of the time, so knowing how to align the clutch with bare vision is a must in this trade!

The tool generally also helps to hold the clutch plate in place while you cover it with the pressure plate more than often people drop it and you end up with a bent clutch plate. This will take you back to square one to start with. I always make sure that my pressure plate is bolted down perfectly before removing the alignment tool

Ahhh the satisfaction!!

It almost looks like the Eye of Mordor! If you look closely you will fall into a time loop. Perhaps never get out of it! Laughs jokes aside it does look pretty neat! Perhaps it's the beautiful grey silver between all the dirty brownness. Also I like to triple check if my clutch is aligned.

Preparing The Gearbox For Fitment

So, I have a question! Have anyone in this group #Hivemotors ever forgotten to put a release bearing on before fitting the gearbox or perhaps forgotten to install the clutch? Well if so fear not for I think a lot of people have! Just the other day I forgot to install the clutch fork I even had the gearbox fitted.

My old man came and stood next to me, as he said jokingly.

"Is this one of those new wireless clutch systems?"

I looked a little bit baffled and more or less stared at where the clutch sits in the bellhousing. Even then I asked.

"Well what do you mean grandpa"

He laughed and said look here, as he pointed to where the clutch fork was suppose to be! Luckily for me I only had two bolts down and removal was quick and easy. But boy did I laugh at myself! Imagine finishing up the whole job just to realize your mistake!

The new release bearing not always needed but 95% of the time we tend to replace it!

This one is now ready and prepped to go back home, so to speak.

Got Errr In Quick And Easy

I've not been working with gearboxes for very long but I can feel the more I work with them the better I understand them, also the faster and more effective I become.

Okay given I do have some proper tools at my disposal and this tends to make everything a lot easier. For example the gearbox jack makes the heavy lifting, well less heavy. Also the fact that I don't have to work on my back on the ground makes me do the job a lot faster. You know being on your feet the whole time.

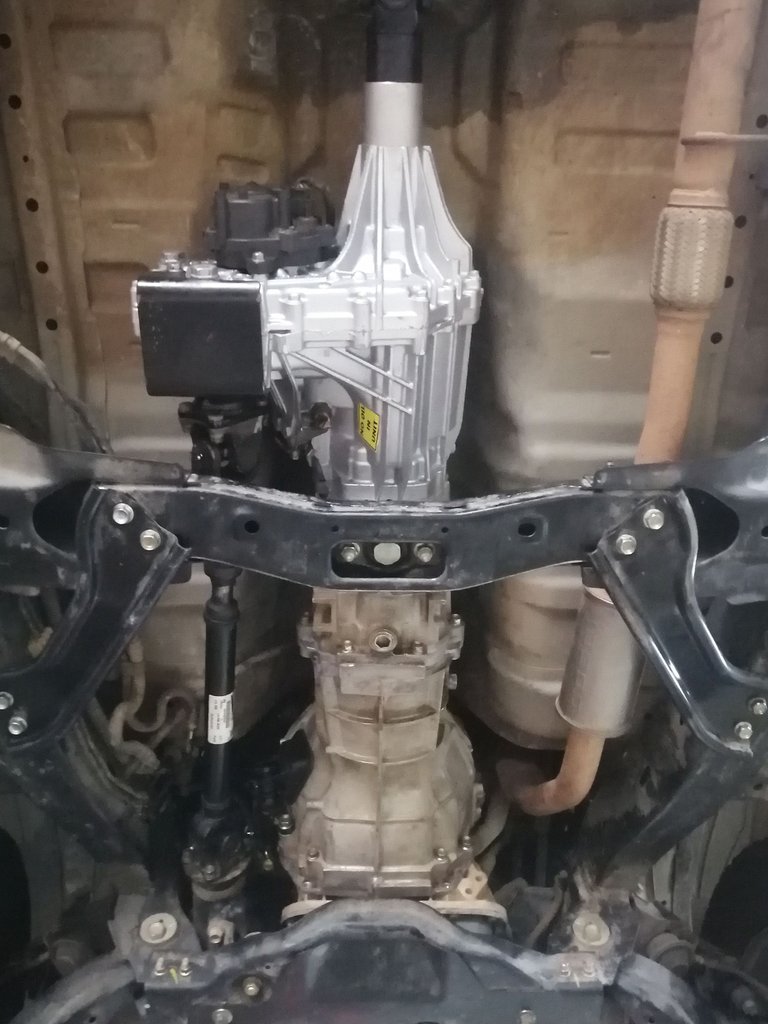

Well I'll be honest I pulled the gearbox back a little bit to get a photo for reference. But it just popped right in, it's a fairly easy gearbox to fit. This is on a Isuzu 2.5 diesel pickup. However it is a 4X4 but it had so much working space compared to the Toyota's and even the Ford's

This specific gearbox doesn't have much to re-fit at and around the bellhousing. While bolting down the bellhousing you can't really miss the starter because it bolts down with everything. So all I added was the slave cylinder that presses the clutch. This means I am all done in-front except for the prop-shaft that enables the 4X4 on the vehicle but that we shall leave for last.

The Gear Lever Was The Tricky Part

Okay so my "old man" sort of warned me over here, but our young one never listen eyyyy! He told me before hand, before I even had the gearbox on the jack that I should remove that little white plastic box at the bottom of the gear lever housing so that I can visually inspect and properly fit the end of the gear lever into the selector shaft.

Needles to say I told him otherwise and that I would be able to guess where it was and just enter it.

Laughs Laughs

I should really start listening to "the old and the grey", and I say this with a lot of respect. More so I should start listening to my "old man"

As you can see that I ended up having to open the white box, with a bit of a struggle now and I was only able to open it a tiny bit. Yes it ended up being a struggle but I was sitting on my ears and being naive so I got my spanking!

The Next Phase, The Transfer Case

Hmmm why is this transfer case so clean you ask! After all we didn't work on it, did we?

Now that's a good question eyyy, well let me tell you! No we didn't not even a bit! Did we wash it? Again Nope!

If I may again refer back to one of my previous posts I shared as to why and how this vehicle ended up at our workshop!

It had a differential rebuild and then when that didn't fix the problem they somehow got the idea the problem was with the transfer case. Laughs what a big mess!

Well let's get that fitted where it belongs, also worth mentioning I love working on new vehicles or should I rather say well maintained vehicles. It's nice and clean no grimey grimes on the hands, all the bolts turn easily. Basically everything is just A grade fun.

On a different note that stud somehow made the job a little bit worse but also a little bit easier, I don't know it's hard to explain.

Right where she want to be! Everything is going smoothly and I am almost done with everything, just a few more stuff to fit.

I always like to do some cable management. Why? Well sometimes the cable's tend to rattle and eventually cut through the wiring protection, this might cause sensors to fail and shorts to occur against the body of the vehicle. More than often a quick and easy fix, it's more of an annoyance I would rather avoid.

Almost Last But Not Yet Least

Okay I've got questions for the person who removed this gearbox, or perhaps I should just keep them to myself! What do you guys think?

So the cross member to the far right as well as the two support mountings at the top I do understand, they need removal in order to remove the gearbox. But the belly plates that are removed is above and beyond my understanding. 😂 They didn't need removal at all. Perhaps he thought it was an automatic gearbox which we needed to turn the crankshaft. However I will refrain from asking questions and silently go on with my work!

Nice and tidy back in their respective places! Lets not to this again! MMMKAAAY.

After fitting the rear and front prop-shafts I was now able to add them fabulous Liquid Gold to the gearbox and call this job done and dusted with.

Looking freshhhh and ready to clutch on!

Only meant to serve as a cover photo

To everyone who made it this far into my post Thank you for the read and the support.

If you found this entertaining or educational please consider a re-blog and up-vote.

Most of all please leave a input in the comments below, whether is good or bad critic I would like to know, whether its your opinion or your way of doing things in a different manner I would like.

Connecting the people of #HIVE across South Africa. #hive

https://twitter.com/1205092265615659008/status/1589713401340911616

The rewards earned on this comment will go directly to the people( @technicalside ) sharing the post on Twitter as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

!ALIVE

PS. You will earn more ALIVE tokens if you add #aliveandthriving too as we have a curation project looking for that tag with the largest ALIVE stake in the tribe behind it.

Made in Canva

Good job that mechanics is very similar to the susuki Vitara here in Venezuela.

You don't say? Ill give it a checkout! Kind of curious to see that one.. I dont work on a lot of suzukis...

Have a good one bud

I have changed the disc, plate and collar of my Fiat Uno car, which is the gearbox kit, of course I have seen how the mechanic does it because I only look after my own interests.

You are the best at what you know what to do keep it up sir

Thanks a lot my man!! Really means a lot! Have a good one bud

It is indeed education, I learned something new today. Greetings from the Philippines!

It's been a while since I was so entertained by a mechanic job posting. It was a very good service.

Laughs, thanks bud. Sometimes it's boring though😄 also not for everyone but I have our little community 😜

Have a good one broh and thanks for the comment!!

!LUV

!PIZZA

@soltecno, @technicalside(2/3) sent you LUV. wallet | market | tools | discord | community | <>< daily

wallet | market | tools | discord | community | <>< daily

HiveWiki - learn from it, help improve it.

HiveBuzz.me NFT for Peace

The gearboxes I used to work on would fit the truck you were repairing. But it still brings me some nostalgia to see a good mechanical work.

I gifted $PIZZA slices here:

@technicalside(2/5) tipped @soltecno (x1)

Learn more at https://hive.pizza!