Small Problems, Big Work

Well Hello There Fellow Technicians And Hivers!

I've got a weird one today!

We worked on the transmission of this pickup, a Ford Ranger. It's been out of the shop for around three weeks and today it came back because of an oil leak.

Before we dive too deep I would like to mention that we took the old transmission and sent it away to our head office and then they sent us back a fully refurbished transmission on which we weren't allowed to fiddle. Which does make sense right? The fiddling part.

Well, here it's coming back with a oil leak and we phoned them and every move they make they sort of blame us for it. Not today my friend not today, they've already sent us a replacement transmission by the time of writing this.

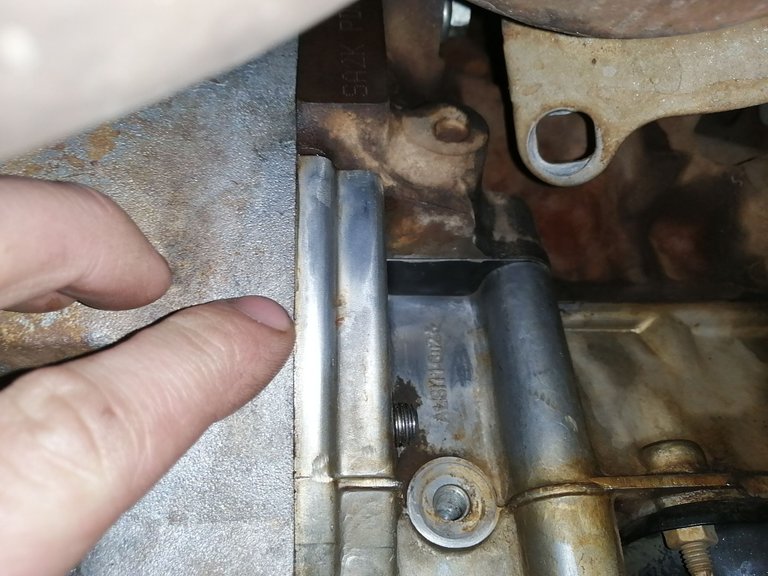

Jumping back into the oil leak, it's a very weird and confusing one. It's not leaking out below the bell-housing, rather it's leaking out from the side of it.

It's hard to explain but here's a few images. We've cleaned it up nicely so it doesn't really look like a major oil leak to be honest but it's a problem none the less.

That's where the oil comes peeling out, but still it doesn't make sense since the bell-housing has a little gap underneath for the oil to drain out, yet it doesn't. I suppose we have to pull this puppy.

There was a lot more oil that filled up at the bottom there than what is showed in the picture, we soaked most of it up.

What surprises me is that the oil never really pushed out that much, very odd. But okay we were doubtfull that it even was a leak on the transmission at first but seeing that clean red oil, well now we know for sure ey.

Before tearing this one apart we will be giving it a nice pressure washing to get it squeaky clean!

Since we did this transmission recently we don't really want to spill the oil. After all it's still very very clean so we can always re-use it in the build when fitting it back.

I cleaned my stripping pan like I've never cleaned it before and also got a freshly washed bucket to catch the oil beneath the table.

What we need to do isn't that big of a job, well that's if you don't count the removal of the transmission. Besides that it's a quicky actually.

Were suspecting that it might be one of the two o-rings in the pump housing or the converter seal that's leaking. Just to be sure we will replace all three of them and have a look at the converter as well. Might be the converter leaking and not the seals.

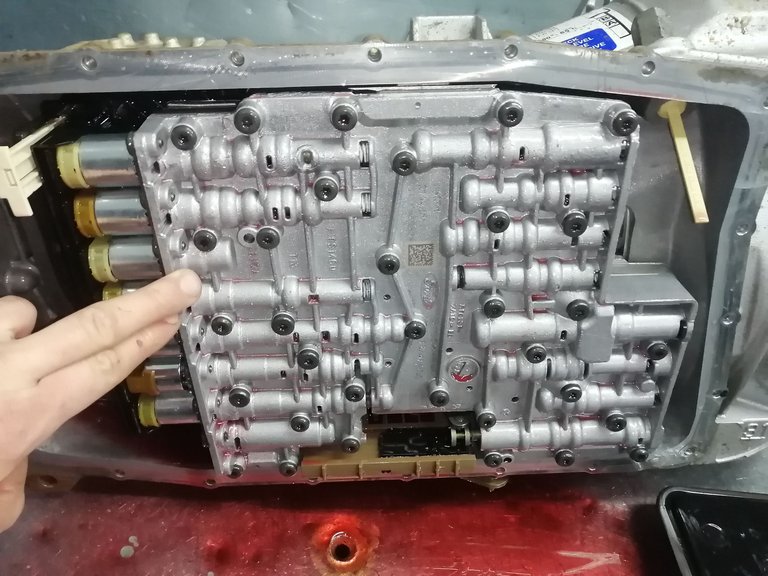

Although before we can remove the pump we have to remove the valve-body first, since it's two parts that interlock with each other.

This is the valve-body, I'm sure most who follow me have seen this once or twice. Before I can proceed that part needs to be removed, just a few bolts and she is out.

Also notice how amazingly clean the oil still is? At-least they built 99% of the transmission the right way. Although I do have to add, a lot of work just to replace a small seal or o-ring.

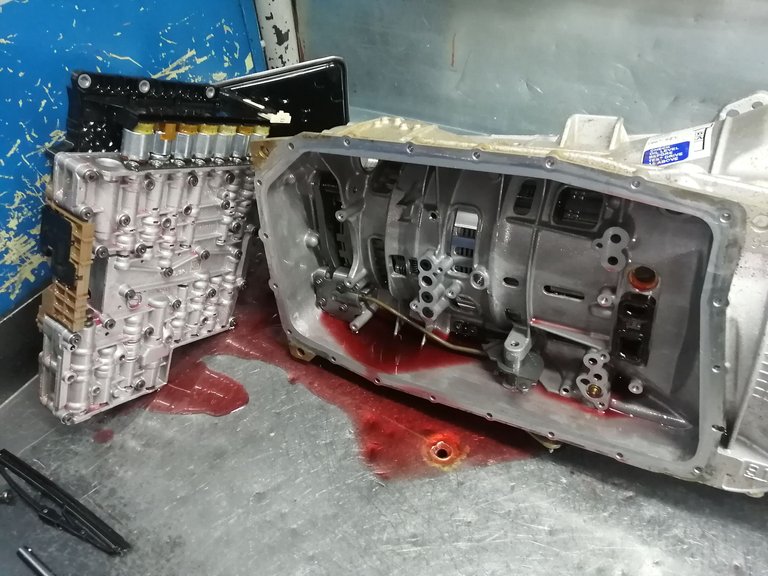

Ahhhhh I think we can push this to the side for a few minutes and have the oil slowly leak out of the transmission, the more we can salvage the better right?

For now I'll be making myself a nice cup of coffee!

Remember earlier I mentioned something of the pump and the valve-body interlocking with one another.

This is part of the pump, so removing the pump before the valve-body is removed is physically impossible. Well not unless you break it and that is never an option, you'd have to remove the valve-body in any case then.

Knowledge is power and very few people know this.

Once I've removed the bolts there is little else to do other than removing the pump.

I wonder how people remove these pumps in the back of their yards without proper equipment and tools to work with, of-course I'm not saying everyone is in that boat but there are surely a lot of them.

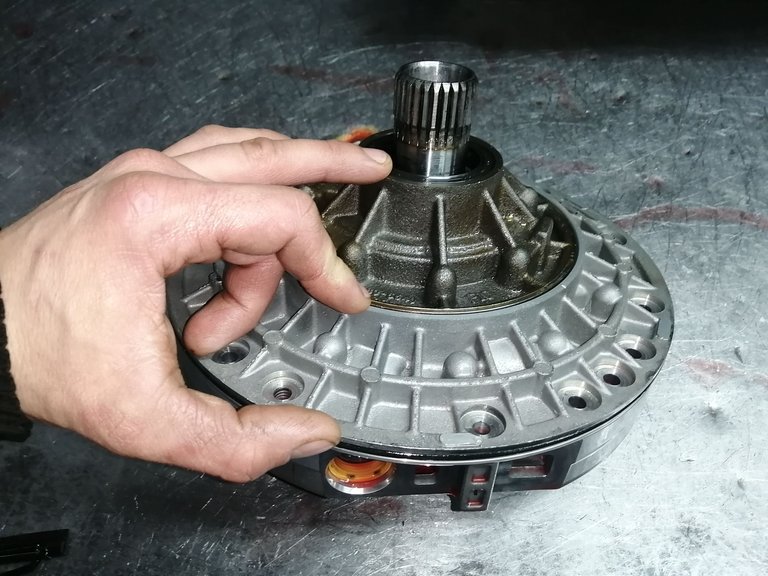

Finally we are where we want to be!

One can't really see all the o-rings, the one is still sealed off.

The top one is the oil seal for the converter, at first we thought it might be that one but inspecting the seal it didn't look damaged at all, in-fact it looked great. We will replace it none the less, as I said it's a lot of work just to replace one seal and we don't want to do it all over again.

The middle one where my index finger is pointing to, well that is the one that is still sealed off. For us to remove that one we need to unbolt the shaft on the bottom (Not important now.)

The bottom one is the one that seals the casing between the pump, now we will be replacing all three of them since it can be any of them. No use in replacing just one and having it leak again, right?

All of them removed and ready to be replaced. The oil seal looks good but we already went over that, we will still replace it.

Now the two o-rings, they didn't look bad but they didn't look great either, the one has some silver paint on it which I have no idea how it got in there in the first place, must be from when the casing was sprayed and perhaps it didn't dry properly before they assembled it.

But before we can slap this whole pump together we have to replace this bush.

Now I'm glad that I noticed this because it would have surely caused some problems later on, it's already worn and how they missed this when rebuilding this transmission is above me.

I know it might be hard to see but that silver ring on the inside, notice how it has marks on it? Now they might seem small but keep in mind that when it's even a little worn oil can bypass and when oil by pass something loses pressure inside the transmission.

Don't let stuff just slide by, everything has an impact however small it may be, sooner or later the small problems grow bigger.

Dated 15/06/2023

Connecting the people of #HIVE across South Africa. #hive

Congratulations @technicalside! You received a personal badge!

Thank you for participating in the Leo challenge.

You can view your badges on your board and compare yourself to others in the Ranking

Check out our last posts:

Great post - I love how clear your photos are ! Something I do is edit them afterwards (in Paint... still the best thing Microsoft ever made 😁) and add in arrows and labels to point at what I'm describing.

I've only ever played with gearboxes twice, although I've got another one I'm just starting to steel myself to do. Looks like you've had lots of practice and really know what you're doing !

Sorry bud I completely forgot to give a response.

Yeah I've thought about it before, but frankly I'm just too damn lazy xD I know I know I shoudn't be but perhaps after my studies I'll be willing to push in some more effort.

I can be honest and tell you I've got so much still to learn, there are a lot of vehicles of which I've never even seen the transmission of, but then again the concept remains the same, this specific one is from a Ford Ranger, but I've done similar stuff on a BMW transmission slightly different but very much the same inside.

Laughs what transmission are you referring to? Manual or auto?

!PIZZA

!LUV

My turn to apologise - I went on holiday for a few days, only just catching up on a zillion messages. Sorry for the late reply !

The gearbox I'm going to work on is in the second spare engine for my Kawasaki Z650, so a manual motorcycle one designed in the 1970's. Hopefully it'll be straightforward, just swapping over an output shaft that's stripped it's sprocket spine.

It can't be as bad as the other one I did, a BMW K100 one (also a manual bike one). I ran into a problem with it, rang our local dealership to see if their mechanics could give a tip, and the answer was "rebuilding a gearbox ? Ooh, you're brave, we just throw them away and bolt a new one on." For the sake of a 50p spring, I persevered, turned out that it only actually needed one of the 16 special tools in the manual, and ran for another 30,000 miles before I sold the bike (and 20,00 after that) 😁

It was opportune that you look at the bushing and also change it, it is better to avoid future problems, thus avoiding that they return to the workshop for the gearbox again.

Yeah, the bush might have lasted for the next six months but how bad would it look for the car to return for the third time😂 and we didn't even rebuild it at first. I don't know why we stopped building them we've built them for a long time. I think maybe getting parts are the problem.

Glad I checked the bush!

Oh sorry for the insane late reply!

!PIZZA

!LUV

https://reddit.com/r/MechanicAdvice/comments/14b6efn/small_problems_big_work/

The rewards earned on this comment will go directly to the people( @ersusoficial ) sharing the post on Reddit as long as they are registered with @poshtoken. Sign up at https://hiveposh.com.

$PIZZA slices delivered:

@technicalside(5/5) tipped @soltecno

technicalside tipped alonicus