The war at the homestead on the gator problems continues.

The Gator repairs continues, with a new fuel pump, an oil change, new battery, a new ignition switch, and fresh fuel is done. But the gator still sleeps.

A second day for electrical troubleshooting was needed! I went back loaded for bear, expecting rodent damage on her wiring harness. The borescope showed zero wiring damage in the sealed areas, sorry, no ways to hold the scope in place, monitor the screen, and get pictures!

As with all John Deere equipment, everything is expensive, including repair manuals. Since this system is reasonably simple, I decided to fix it without. Since I started using meters before they were digital, I had an edge.

Locating power on the switch harness was a little difficult, even knowing wiring conventions. Ground (black) was solid to the battery, but there was no connection to the positive (red) lead.

Here's where the meter jumped in:

The new switch tested out and showed me which lead fed the ignition, but I couldn't find the starter solenoid wire that fires that solenoid.

Looking on the solenoid, the wire showed it was purple, and traced to the switch. The wire was good In the harness, but the new switch was broken; and didn't provide the 12 volt start signal! A new, 'new' switch is coming. The joys of chinese quality control....

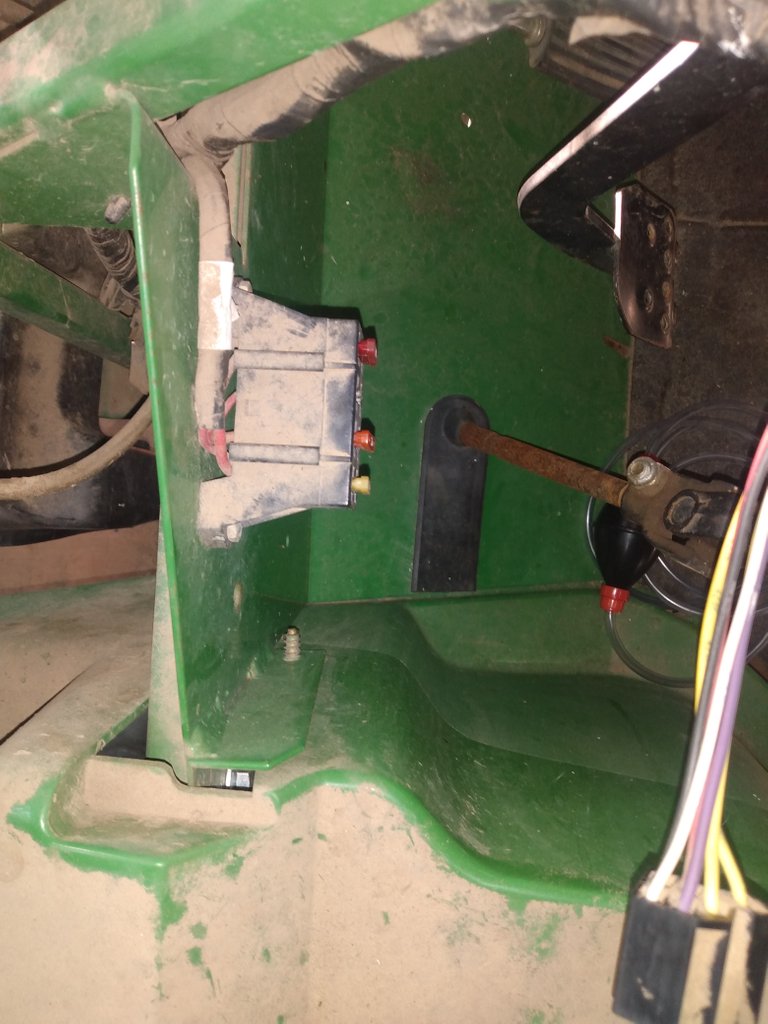

Then it was time to tangle with the supply power:

With a little digging (knowing that John Deere makes good gear) I found a fuse block under the hood, complete with a blown blue fuse (the empty spot). Sticking in a spare red one for testing, I found that the wiring was in good shape!

This is where the fuse block was hiding:

Protected by the hood of course.

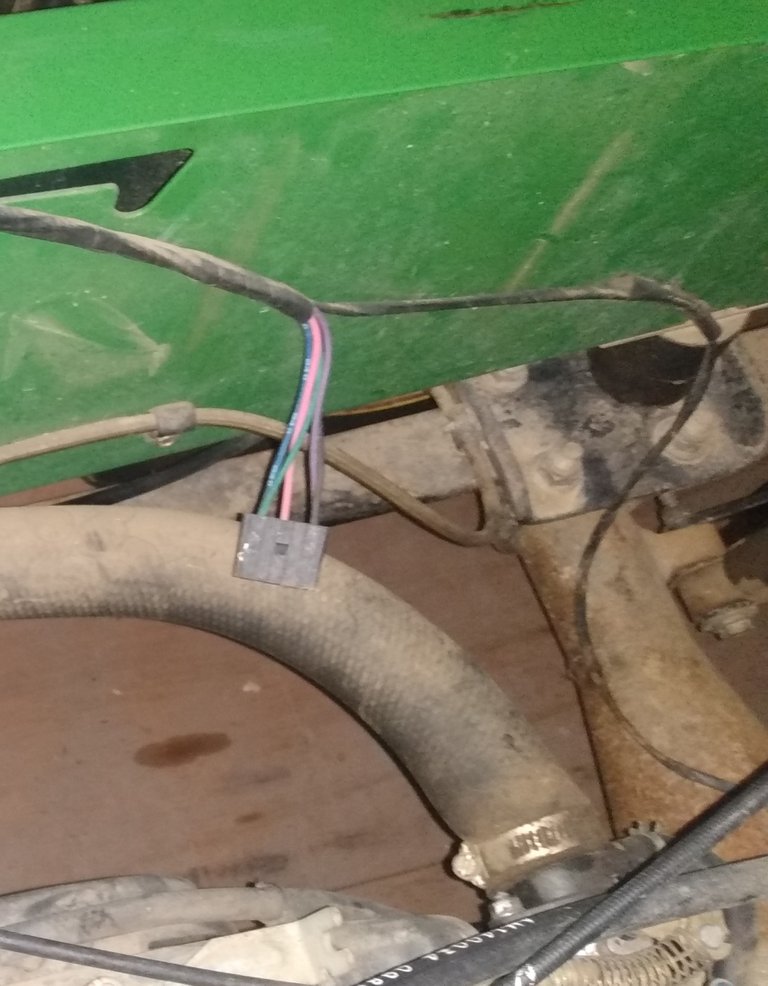

Next was testing the ignition wiring:

The switch showed me where the ignition power was, on a yellow lead.

There were multiple yellow drops:

While all were working, the 'S' shaped wire here is the magneto power for this system. The shape avoids any tension problems in the harness!

The other drops are for accessories that need to be turned on for use, and off to preserve the battery.

I will have the new switch this weekend, and hope to get back after it early next week.

The only remaining items are new front shocks, which are due in soon also!

I'm keen to see it up and running, I'm sure you are chomping at the bit for the same...the wiring without a manual, you know your stuff but I get that most of these things are sometimes simple if you just follow through the most basic first like fuses. Rodents can chew up and short out all sorts of things so it was a relief to read that it wasn't that.

I know it'll roar to life again soon, I hope all your electrical bits come with minimal supply issues.

Gater is a cool name by the way 😁

I need it running to carry water from lake Keystone, to help me drill a well. I'll need about 700 gallons on site before I start drilling. It will need to go down to about 120 feet for reliable water, but the drill is designed to go 250 feet deep. I'll haul one 55 gallon drum at a time to avoid getting stuck.

Later it will haul dirt for my Wallipini greenhouse.

My Wife thinks I should call the gator, 'Alli'; and since I taught her to shoot....

😁😆👍🤠💗😋🙏

Ah ok, that sounds like a big project going down 120feet. That's like 35 meters! I have no idea what is required for that kind of project in terms of prep work but once Alli is up and running, I'm sure she'll make it happen in no time.

I think you are wise to take your wife's name suggestion on...unless you want a bullet with your name on it lol 😁

Thanks for the explanation Toby, I'm keen to see how your well comes on.

I bought an air powered drill guaranteed to reach 250 feet, but it uses a Lot of air and water. I will be manifolding 3 compressors to get the required flow rate. It's complicated by the off grid nature of the homestead, but it's planned for.

Yup that Gator is officially 'Alli' gator now! She's got hollow points....

😆😁👍💗😋🤠🤕😳

Manifolding 3 compressors - you make it sound way easier than it is. I hope it all goes well with few complications or your wife is not going to be impressed with Alli.

I have a machine shop. It will take a piece of heavy aluminum bar stock, deep drilled and tapped to form the manifold. I already have the check valves purchased, to isolate the individual compressors. I need 16 cfm and will have 25 from this manifold.

I'm sure Alli will do just fine, LOL! There are hundreds of acres of Corp land, along the lake shore for her to roam on.

👍💙🤠😁🙏🌿🥦🐟

It sounds like that manifold will do it with ease. Having a machine shop must make things so much easier as if you can't source a part, you can probably make it yourself. I miss having a workshop. One day I'll have one again to be able to do all my DIY stuff.

Alli is going to pay for herself time and time again, she'll be a real work horse and will earn her keep. I'm quite fond of her already, can't wait to see her roar to life 🙂

Keep well Toby, always nice hearing from you.

The shop is handy for sure. I'm installing a satellite shop at the homestead with a knee mill and metal lathe. The heavy equipment will need to wait on a shop building, can't build it all at once!

The electronics bench fills the other half of the build it needs.

Alli is a big part of my planning out at the homestead. I have to dig a 14' by 60' hole 4' deep for the wallipini greenhouse. My backhoe will dig it, and Alli will haul the dirt away to make the north berm wall. If things go to plan, I won't have to touch any dirt during the build!

But the well is first....

👍🤠💙🙏💗😁💸🌊💵