Cement and its manufacturing process

Source

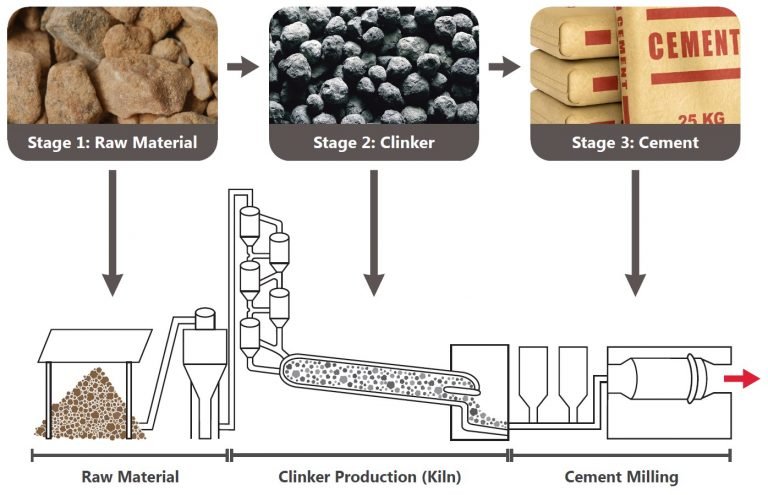

Cement is a powdery, binding material that is widely used in construction. It is obtained from a mixture of limestone and clay that is subjected to a firing process at high temperatures.

During this process, the components fuse together and form the so-called clinker.

The clinker is finely ground to obtain cement in powder form. This powder is then mixed with other materials, such as gypsum, to regulate its setting time and improve its physical properties.

When cement is mixed with water, a chemical reaction known as hydration occurs. This reaction causes the cement to harden and acquire its characteristic strength.

Source

Once hardened, cement forms a solid, strong mass that is used to bind and fix other building materials, such as bricks, stones and blocks.

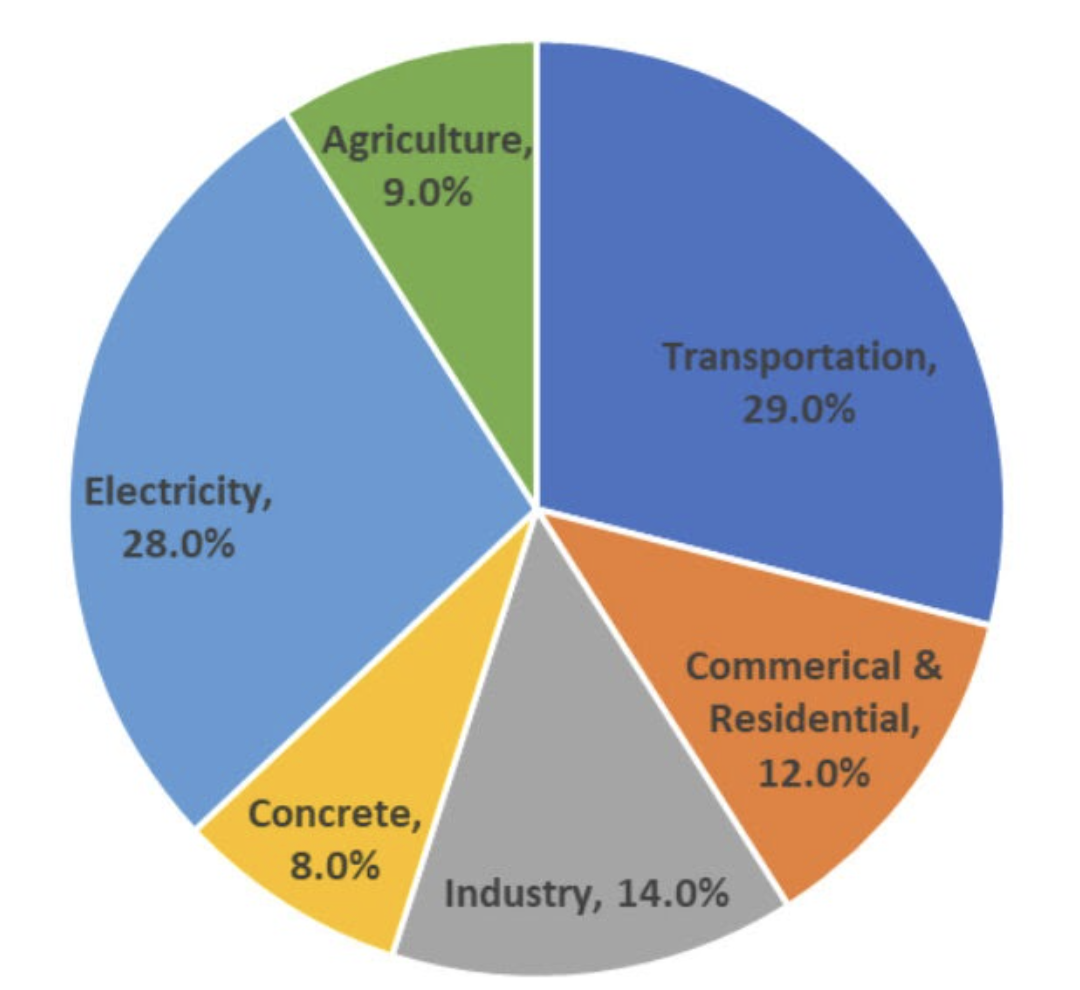

Cement is widely used in the construction of structures such as buildings, bridges, roads and dams. It is also used in the manufacture of concrete, which is a mixture of cement, sand, gravel and water.

Concrete is a strong and versatile material used for the construction of foundations, slabs and other structural elements.

The Process for making concrete is as follows:

Source

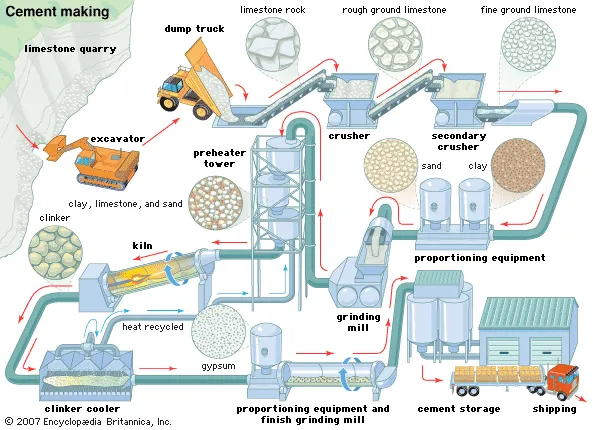

Extraction of raw materials: The first step in the manufacture of cement is the extraction of the necessary raw materials. These include limestone, clay and gypsum. They are extracted from quarries and mines.

Crushing and grinding: Once the raw materials have been extracted, they are taken to the production plant and crushed into small fragments. They are then ground into a fine powder in a mill.

Preparation of the mixture: The powder resulting from crushing and grinding is carefully mixed in specific proportions. Limestone and clay are combined in a suitable proportion to obtain the desired composition.

Source

Firing: The prepared mixture is placed in a rotary kiln at high temperatures, around 1,450 degrees Celsius. This process, known as firing, aims to melt the components of the mixture and form clinker, which is a kind of granular material.

Grinding the clinker: Once the clinker has cooled, it is ground together with a small amount of gypsum to obtain the final cement. This stage is important to obtain a fine and homogeneous powder.

Packaging and distribution: The ground cement is packed in bags or stored in bulk in silos. It is then distributed to customers, either for use in the construction of structures or for sale to other manufacturers.

0

0

0.000

Congratulations @danielpardo! You have completed the following achievement on the Hive blockchain And have been rewarded with New badge(s)

Your next target is to reach 70 posts.

You can view your badges on your board and compare yourself to others in the Ranking

If you no longer want to receive notifications, reply to this comment with the word

STOPTo support your work, I also upvoted your post!

Check out our last posts: