What is the process of drilling and completing coalbed methane (CBM) wells like?

The process for drilling and completing wells in coalbed methane gas wells is very similar to that of wells in conventional reservoirs, however, there are some minor differences including coring and geological data collection during drilling.

When designing a drilling program for these types of wells, it is necessary to collect existing information about the wells in the area where it has been agreed to drill the well. It is important to collect the depths and reservoir pressures of the wells neighboring the well to be drilled, so that a drilling mud density versus depth design can be adjusted.

In general, it is important that the data to be collected have a correct correlation and thus minimize calculation errors in the design of the drilling program of this type of wells.

Teamwork is very important, especially taking into account the set of professionals with multidisciplinary characteristics that exist for this type of design, so it is advisable that after collecting and analyzing the geological data, a preliminary prognosis type report is drafted, explaining in detail how the drilling and completion operations of this type of wells can be.

One small difference in this type of wells, relative to conventional oil well drilling is that because carbon-layer methane wells are drilled at very shallow depths relative to conventional wells, very different drilling rigs are used than conventional wells, both onshore and offshore.

What drilling mud can these wells be drilled with?

One of the geological data previously obtained from neighboring wells is the reservoir pressure, this data together with the type of coal to be drilled gives us an idea of the type of drilling fluid to be used in the drilling, among which we can highlight between conventional muds, water and aerated fluids.

How are the completions in this type of wells?

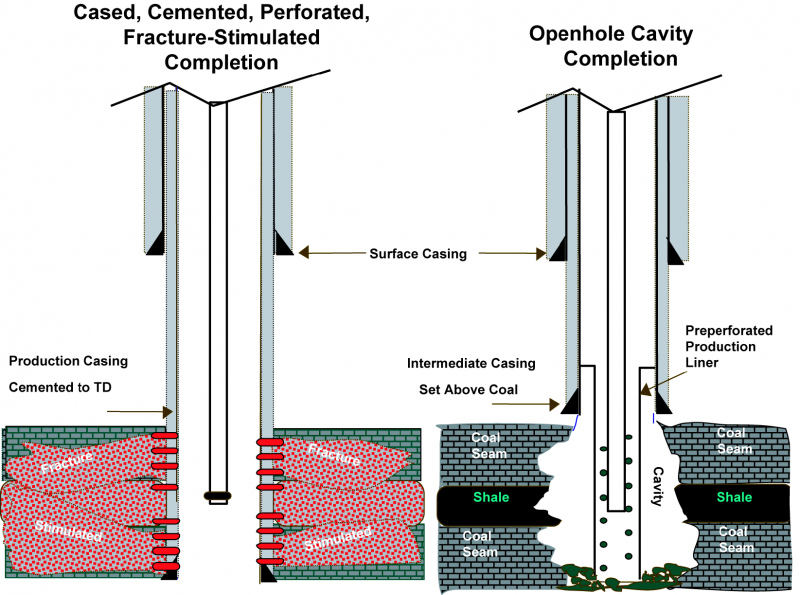

CBM wells are cased in the same way as conventional wells, the difference is that the coal seams must be hydraulically fractured, so depending on the type of permeability present in the coal, the type of fracturing to be performed will be determined.

An example of high permeability is an indication that there is stability in the walls of the well, so the well can be completed open hole.

In conclusion, the differences studied will depend on the geological characteristics found in the reservoirs of this type of wells, so the works that will vary the most are those of well completion, occurring small variations for drilling processes.

References

[1] Diamond, L.W. and Trotter, G.L. 2000. The International Workshop on Opportunities for Coal Mine Methane Projects. Beijing, China: CDX Intl. LDC.

[2] Rogers, R.E. 1994. Coalbed Methane: Principles and Practice, 345. Englewood Cliffs, New Jersey: Prentice Hall.

Nice post, informative. I just joined hive, but also work in oil and gas, I build control systems for service rigs and hydraulic fracs with a lot of sensor and instrumentation control at the surface of the well. Nice to read your content here and meet you!

Hello friend, glad you can share with all of us your knowledge of petroleum engineering, and what country are you from?

@carlos84, THANKS! I'm from Canada, and many of my clients are in the US, so most of the work I've done is on equipment in the US.

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.