Engineering involved in petroleum well planning

Petroleum engineers and other branches involved are in the obligation to plan everything related to the planning of an oil well, the planning of an oil well is one of the most demanding aspects within the field of engineering, since planning requires the integration of a multidisciplinary group that involves the contribution of the knowledge of various professionals such as petroleum engineers, geologists, mechanical engineers, among others.

The planning of a well goes beyond the contributions of engineering, since being an ambitious project, in all cases corporate philosophies must be integrated that when involved with experience factors can be achieved to develop oil well planning projects that meet the engineering and corporate requirements necessary for the construction of the well to be carried out in the shortest time, with the lowest costs and where the least operational problems occur.

The generalized objective when deciding to plan a project in the construction of an oil well is that all the methods for the construction of the well are exposed and explained in the planning and whose operational practices are exposed in a clear and concise way so that the supervisors, engineers and workers have a guide where they can be guided in this process. The well planning must allow the well construction to be done with operational practices that are safe and where the guidelines given by the reservoir engineer in relation to hydrocarbon production can be satisfied.

What is the philosophy to be able to expose the minimum cost criteria in the planning of a well?

Certainly the planning of a well must take all the processes in the construction of a well under the philosophical standards of low cost, however this can only be carried out as long as the safety and integrity of the personnel working and also the equipment involved is not harmed.

A clear example used in engineering is when a series of mathematical calculations are made to determine the maximum collapse and burst pressure that the casing pipe can withstand at a certain depth, since the greater the resistance of the casing pipe, the more expensive it is, and lowering a pipe that is above the required resistance is an over design, while the ideal is to choose the pipe that withstands such pressures but within the minimum ranges that are the least expensive.

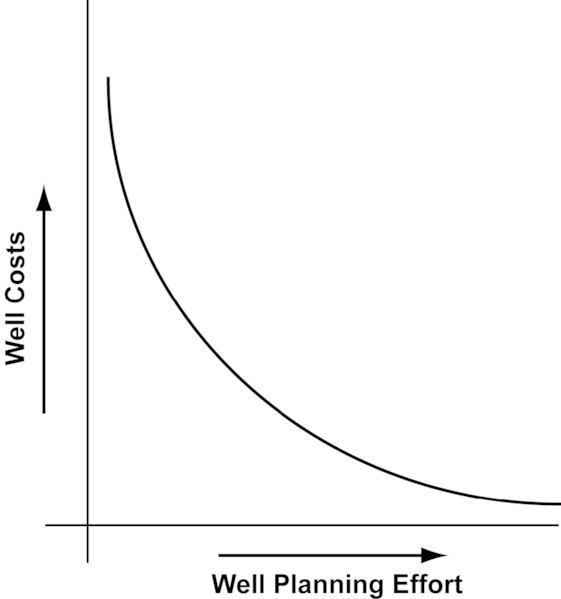

In the previous graph we can see evidenced how as the days go by the effort in the planning of the well makes the costs associated to the construction of the well go down, while when the costs associated to the construction of the well increase it is because the planning efforts of the well are just beginning, which makes us conclude that by experience in the application of diverse plans of construction of wells while the planning effort is maintained the planning costs will also go down in relation to the estimated costs.

References

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.