Causes and solutions to stuck drill pipe problems

In the drilling of oil wells the least desirable thing is for the drill pipe to get stuck, since in the case of getting stuck at the bottom of the hole and when trying to recover the pipe a tensile force may be applied to it that exceeds the limits of elasticity to rupture. In the event that the drill pipe breaks off at the bottom of the hole there is the likelihood that the well and all tools attached to the drill pipe will be lost.

The costs associated with such losses are expensive, apart from losing everything that has been built in the well, to avoid such economic losses associated with what was initially a stuck pipe, the causes of the stuck pipe must be studied and evaluated, since being able to diagnose the causes can help us to take preventive actions in drilling operations and construction of the oil well.

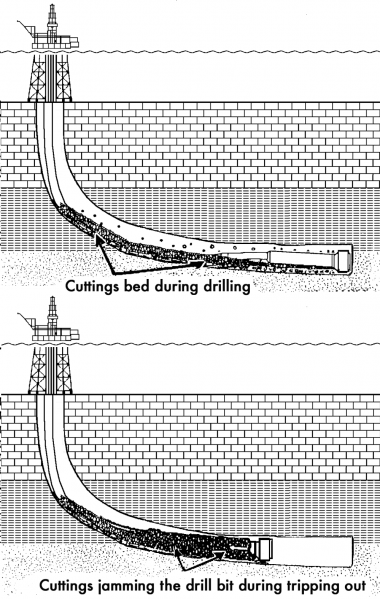

The causes of mechanical sticking of the pipes are for example an inadequate cleaning of the drill cuttings between the space between the walls of the well and the walls of the drill pipe (annular space). If there is an inadequate cleaning of the drill cuttings what will happen is that the drill cuttings will accumulate at the bottom of the hole causing the pipe to get stuck as shown in the following image:

The solution for this case once the cause is identified is to correct the drilling fluid parameters that are involved with the effective cleaning of the hole, such as viscosity, circulation velocity, among others.

The interesting thing about applying the knowledge of petroleum engineering in drilling wells is that we engineers are taught that all wells are not the same and therefore must be treated and analyzed according to their characteristics.

A clear example is when we are drilling a well that is presenting drags through high torques of the drill pipe, and when we check for example the drilling fluid circulation we realize that an effective cleaning of the hole is occurring, so the problems of high torque is not because of problems in the cleaning of drill cuttings, that is where we wonder:

What could be happening because of the high torque and drag problems?

The previous geological study before drilling is fundamental, because if the zone whose interval is being drilled is shale then the problems to be presented are of instability of the well, so the solutions are different from those when the causes are due to bad cleaning of the drill cuttings.

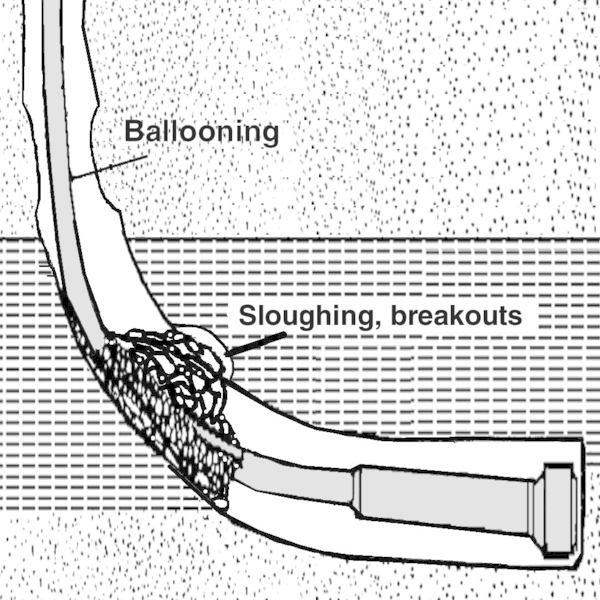

One of the solutions to avoid hole instability due to problems of drilling shale zones, is to design a drilling fluid that contemplates an oil-based drilling fluid, because if the drilling fluid is water-based shales swell and detach into the well, if we manage to prevent the shales from swelling we will also prevent the drill pipe from sticking mechanically to the walls of the well, as shown in the following image:

What signs may occur in the wellbore before a tubing stick occurs due to wellbore instability?

As it is well known the drilling fluid returns to the surface through the annular space, but if the well begins to plug at the bottom due to a mechanical sticking, the first thing that will manifest itself is an increase in the circulating pressure of the drill pipe, so if we begin to observe an increase in this type of pressure is because a mechanical sticking is occurring and we must act before the drill pipe is finished sticking mechanically completely.

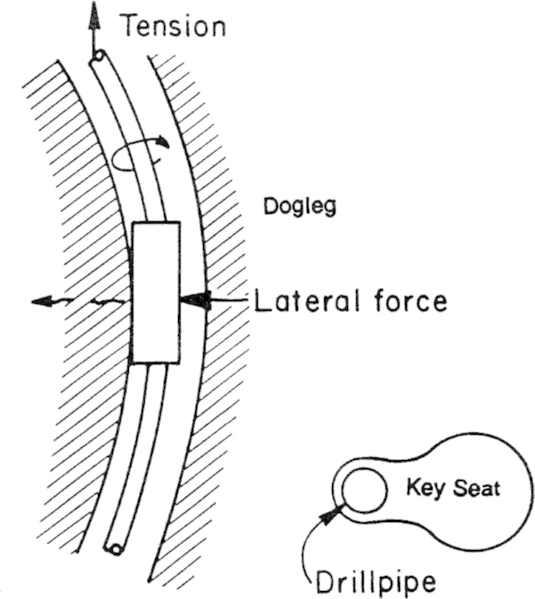

There are also other cases of mechanical sticking of pipe that are caused by sudden rotational movements of the pipe, and where the larger diameter parts of the pipe can get stuck in the parts where the well has a pronounced deviation, knowing that this occurs in wells drilled directionally and inclined, an example of this is shown in the following image:

Conclusions and recommendations

Once the drill pipe is stuck can it be freed?

As I have mentioned previously, we can not speak of unique solutions, since each case is particular, so if a well being drilled presents a stuck pipe problem, the most convenient would be to solve the stuck pipe depending on what is the cause of the jamming.

For example, if the drill pipe is already stuck and its causes may be due to accumulation of drill cuttings or detachment of the walls of the well, what should be done is to rotate the drill pipe string while increasing the flow rate values in the circulation of drilling fluid, although it is necessary to be very careful and take care that when increasing the flow rate does not exceed the maximum allowable values of the equivalent circulating density (ECD), with these movements there may be the probability that the pipe will come out of the jam and the integrity of the well can be saved.

If on the contrary the cause of the stuck pipe is the narrowing of the well due to shale swelling, perhaps we can free the drill pipe string by increasing the values of the drilling fluid density (mud density), while increasing the mud density and circulating at a controlled flow rate can work the movements of the string in rotation and tension but without exceeding the torque and drag values and the maximum allowable values of being able to tension the pipe string.

In the case that the pipe can not be released, and as the days pass and keep trying and the jam is not released, then increases the likelihood that it can not be released, so it is best to tension the drill pipe until the pipe breaks by exceeding the limits of tension, then a cement plug is pumped to make a subsequent diversion of the well and continue drilling and construction of the same.

References

Thanks for your contribution to the STEMsocial community. Feel free to join us on discord to get to know the rest of us!

Please consider delegating to the @stemsocial account (85% of the curation rewards are returned).

You may also include @stemsocial as a beneficiary of the rewards of this post to get a stronger support.

Thanks for support